Home » AC Servo Motor » 2 kW AC Servo Motor

2 kW AC Servo Motor

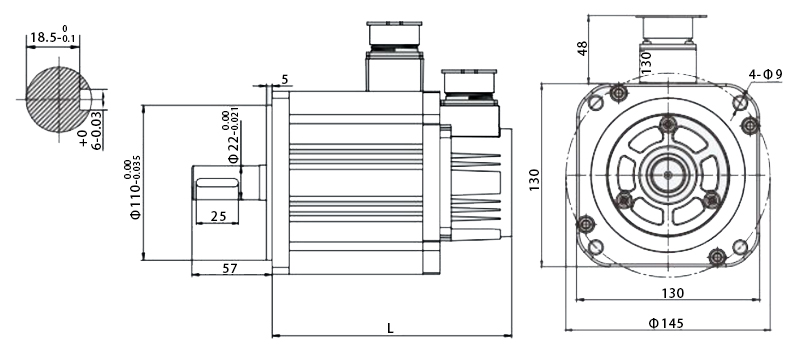

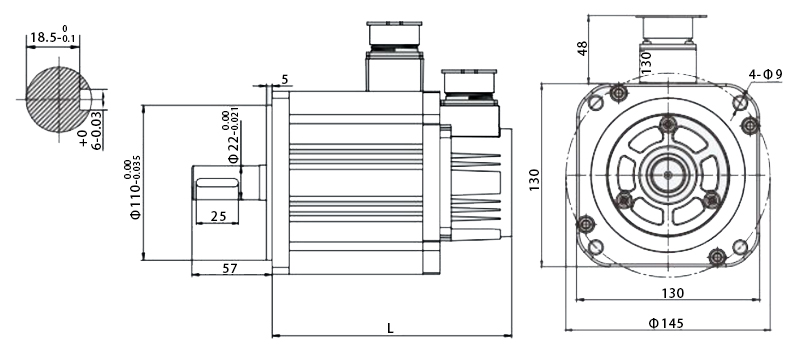

The 2 kW high-torque servo motor is characterized by a brushless design, operating on a 3-phase 220V AC voltage with a nominal speed of 2500 rpm, capable of reaching a maximum speed of up to 2800 rpm. This heavy-duty electric servo motor features a 130mm square flange size, rendering it suitable for a diverse range of applications in industrial automation, including embroidery machines, printing machinery, CNC machines, wood carving, and various other fields. Its robust design and high-torque capabilities make it a versatile and reliable choice for demanding tasks across different sectors of automation and machinery.

Basic Specifications

Buy 2 kW AC Servo Motor Now!

ATO AC servo motors excel in various aspects, ensuring precision through closed-loop control of position, speed, and torque, effectively overcoming issues associated with stepper motors, such as out-of-step occurrences. These motors exhibit impressive high-speed performance, with a rated speed range extending from 1000 to 3000 rpm. Renowned for their adaptability, ATO heavy-duty servo motors demonstrate a robust anti-overload capability, capable of withstanding loads three times the rated torque. This feature makes them particularly suitable for applications with sudden load fluctuations and a need for swift starts. Ensuring stability, these AC brushless servo motors operate smoothly at low speeds, eliminating stepping phenomena common in stepper motors and proving ideal for scenarios demanding fast responses. The motors exhibit prompt dynamic response times for acceleration and deceleration, typically within tens of milliseconds. Furthermore, prioritizing safety, ATO AC servo motors come with an IP65 protection grade, meeting stringent waterproof and dustproof requirements.

Basic Specifications

Model: ATO130SY-M07725

Rated Power: 2000 W

Rated Voltage: Three phase 220V AC

Matched Drive Model: ATO-SG-AS302600

Rated Current: 7.5 A

Rated Speed: 2500 rpm

Max Speed: 2800 rpm

Rated Torque: 7.7 Nm

Peak Torque: 22 Nm

Square Flange Size: 130 mm

Weight: 10 kg

Buy 2 kW AC Servo Motor Now!

ATO AC servo motors excel in various aspects, ensuring precision through closed-loop control of position, speed, and torque, effectively overcoming issues associated with stepper motors, such as out-of-step occurrences. These motors exhibit impressive high-speed performance, with a rated speed range extending from 1000 to 3000 rpm. Renowned for their adaptability, ATO heavy-duty servo motors demonstrate a robust anti-overload capability, capable of withstanding loads three times the rated torque. This feature makes them particularly suitable for applications with sudden load fluctuations and a need for swift starts. Ensuring stability, these AC brushless servo motors operate smoothly at low speeds, eliminating stepping phenomena common in stepper motors and proving ideal for scenarios demanding fast responses. The motors exhibit prompt dynamic response times for acceleration and deceleration, typically within tens of milliseconds. Furthermore, prioritizing safety, ATO AC servo motors come with an IP65 protection grade, meeting stringent waterproof and dustproof requirements.

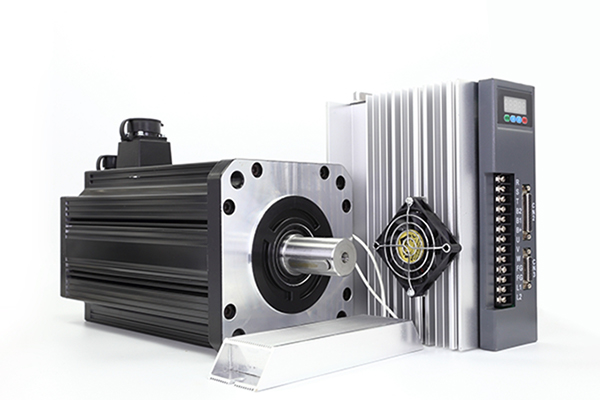

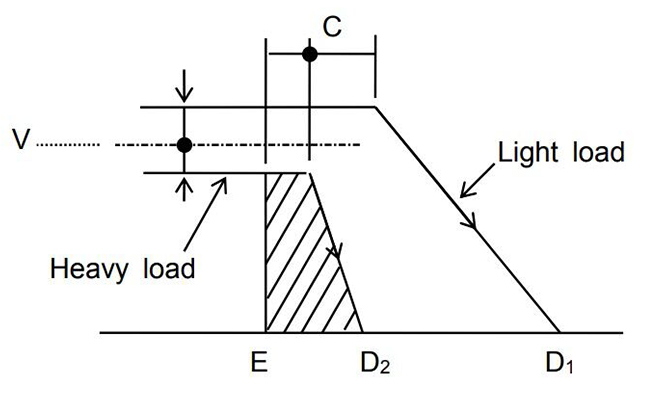

When dealing with the allowable shaft terminal load for servo motors, it is crucial to manage both radial and axial loads applied during installation and operation within the specified limits for each model. Particular attention should be given to the installation of rigid couplings, as excessive bending may lead to damage or wear on the shaft terminal and bearing. Opting for a flexible coupling is recommended to keep the radial load below the allowable value, enhancing the overall performance and longevity of the servo motor. This flexible coupling is specifically designed to complement servo motors, offering high mechanical strength and contributing to a more efficient and reliable operation.

Post a Comment:

You may also like:

Category

Featured Articles

What is Position Control by AC Servo?

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

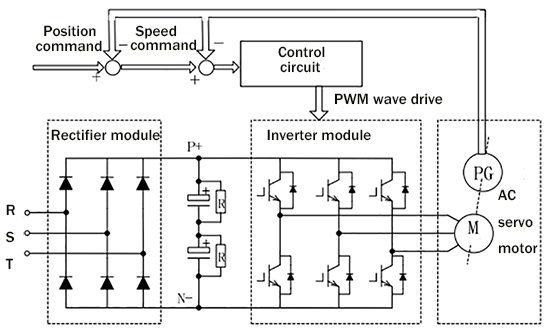

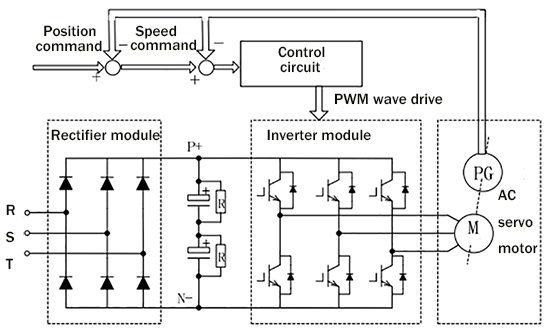

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...How to Wire an AC Servo Motor?

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

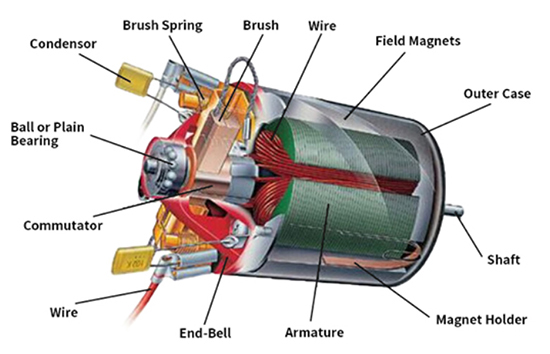

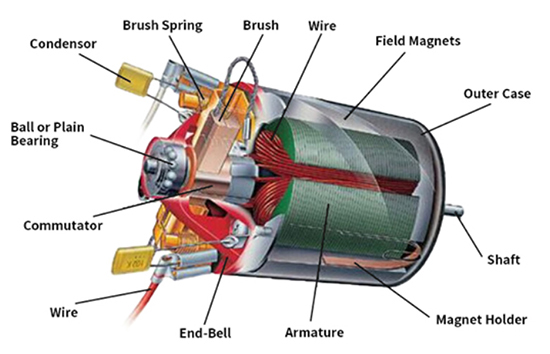

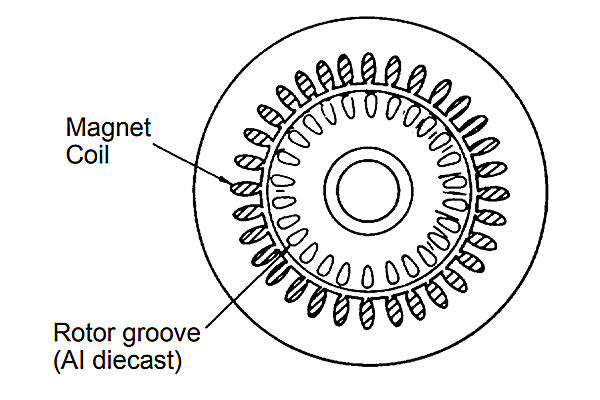

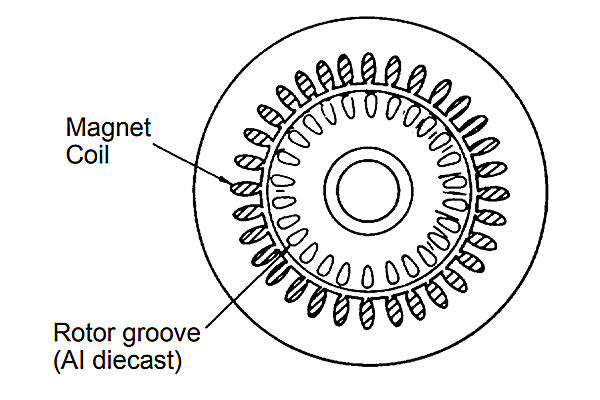

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...AC Servo Motor: Structure, Working and ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...What is Operation Principle of AC ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...