AC Servo Motor: Structure, Working and Application

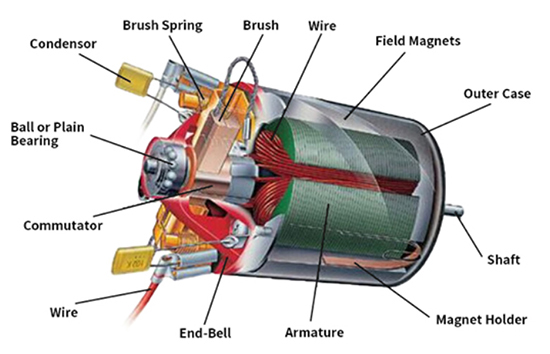

AC motors construction

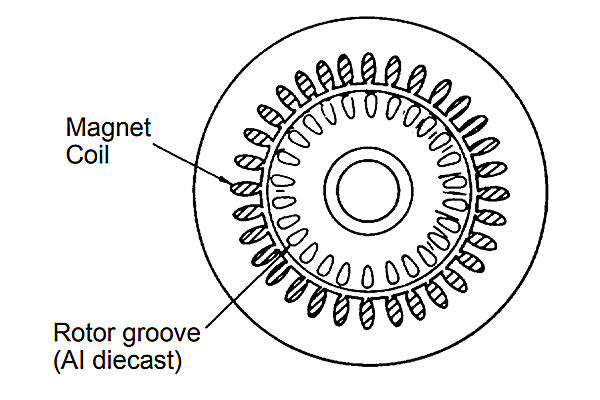

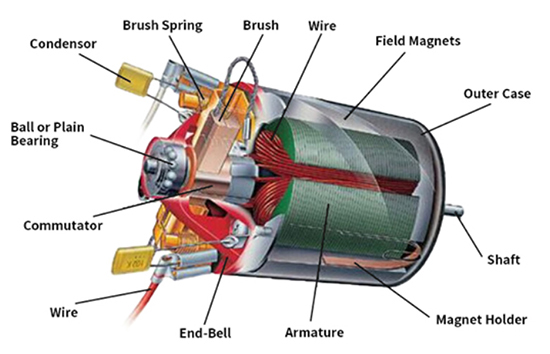

The stator consists of laminations and has salient poles. Usually, the stator poles are provided with two poles or four poles, and machine-wound excitation coils are used. The rotor is also laminated with slots to accommodate the armature windings. The rotor windings are connected to commutator segments mounted on the shaft. The stator and rotor windings are connected in series with the help of high-resistance brushes (placed on the commutator). Armature reaction causes a reduction in air gap flux. To compensate for the same, compensating windings are connected in series with the stator winding.

The working principle of an AC servo motor is the same as that of the DC series motor. The armature and field are wound

and interconnected in the same manner as the DC motor.

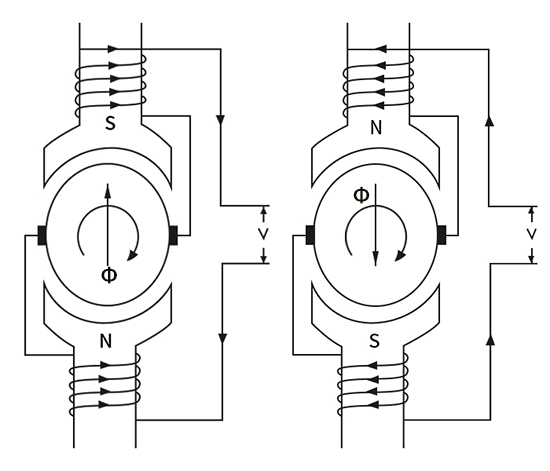

During the positive cycle, assume that the

top field pole in the figure below is SOUTH. The direction of the current is on

this surface. When applying Fleming's Right-hand rule, we can see that the

direction of torque (force) is in the clockwise direction.

When an alternating EMF is applied to the

terminals since field and armature windings are connected in series, the field

flux and armature current reverse simultaneously every half cycle, but the

direction of the torque remains unchanged.

The torque is pulsating, but its average

value is equal to that which a DC servo motor would develop if it had the same RMS.

In each half cycle, the magnetic polarity as well as armature current direction

reverses.

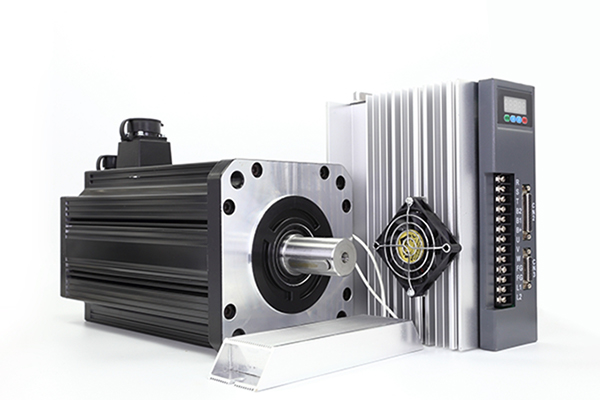

Application

AC servo motors are widely used in many industries. It is used in industrial automation, robots, new energy industry, automobile manufacturing, aerospace, medical equipment, logistics and transportation and other fields. It plays an important role in transmission and smart homes.

Industrial automation: AC servo motors are widely used in various production lines in the field of industrial automation due to their high efficiency, accuracy and reliability. For example, they can drive pumps, fans, conveyor belts and other equipment to increase production efficiency and reduce energy consumption. Robot technology: In the field of robot technology, the importance of AC servo motors is self-evident. Every movement of the robot, whether it is the rotation of the wrist or the opening and closing of the fingers, requires precise motor drive. AC servo motors can provide stable and precise motion control, making the robot's movements smoother and more precise.- New energy industry: In the new energy industry, the utilization of renewable energy such as wind energy and solar energy requires precise motor control. AC servo motors have fast response and accurate adjustment, which play an important role in improving the utilization rate and stability of new energy.

-

Automobile manufacturing: In the

automobile manufacturing process, AC servo motors are used in various

equipment, such as engine assembly lines, braking system testing equipment,

etc. Its efficient performance and precise control play a key role in improving

production efficiency and product quality.

-

Aerospace: In the field of aerospace,

the application of AC servo motors is even more special. Since the weight and

performance requirements of equipment in this field are extremely strict, AC

servo motors are often used to drive various precision instruments and

equipment.

- Medical equipment: In the field of medical equipment, the precise control and continuously variable speed characteristics of AC servo motors are widely used in various medical equipment, such as CT scanners, MRI instruments, etc., which can improve equipment performance and reduce equipment costs and energy consumption.

Post a Comment:

You may also like:

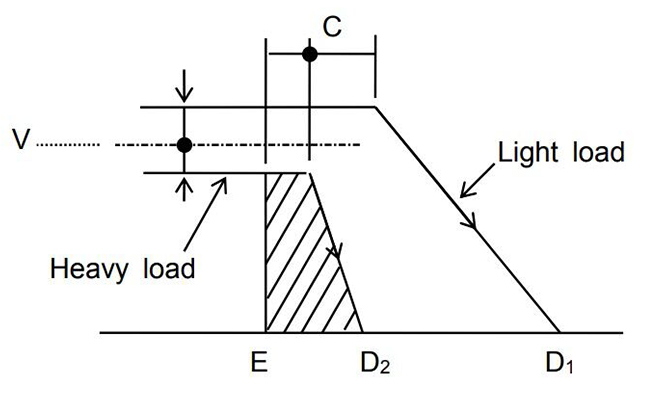

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ... A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ... The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ... AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...