Home » AC Servo Motor

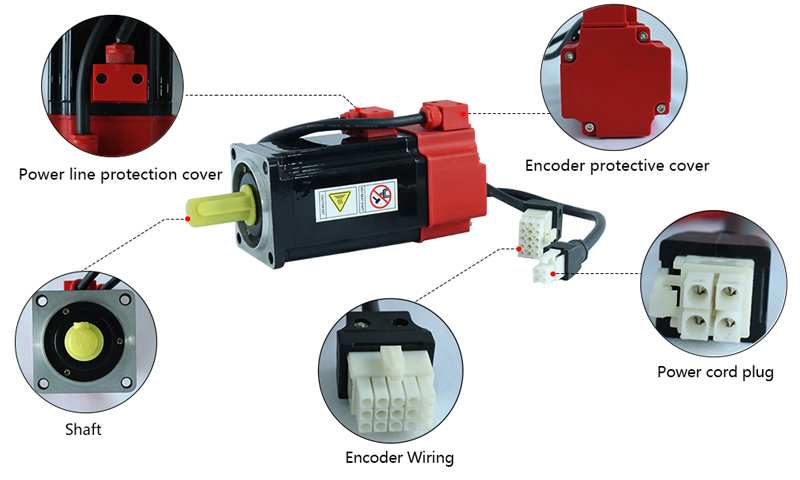

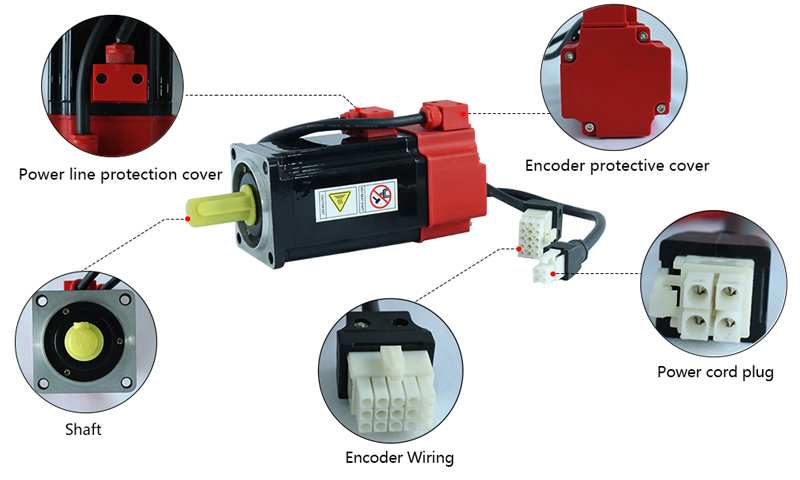

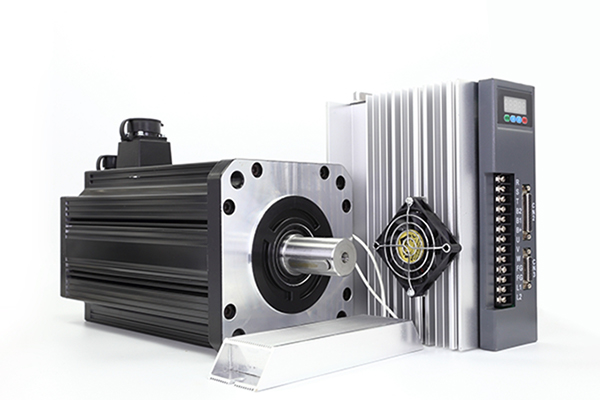

AC servo motor is a type of electric motor specifically designed for precise control of angular or linear position, velocity, and acceleration. ATO factory focuses on the production of high precision servo motors. 50W AC servo motor with brushless design, rated speed of 3000 rpm, maximum speed up to 3600 rpm.

The suitability of AC servo motors for harsh environmental conditions depends on the specific design and construction of the servo motor as well as the severity of the environmental conditions.

The suitability of AC servo motors for harsh environmental conditions depends on the specific design and construction of the servo motor as well as the severity of the environmental conditions.

In order to keep the 50W industrial servo motor running steadily in harsh environmental condition, we can choose a servo motor with appropriate materials and coatings to resist corrosion; with appropriate seals and coatings to prevent moisture ingress.

The suitability of AC servo motors for harsh environmental conditions depends on the specific design and construction of the servo motor as well as the severity of the environmental conditions.

The suitability of AC servo motors for harsh environmental conditions depends on the specific design and construction of the servo motor as well as the severity of the environmental conditions. In order to keep the 50W industrial servo motor running steadily in harsh environmental condition, we can choose a servo motor with appropriate materials and coatings to resist corrosion; with appropriate seals and coatings to prevent moisture ingress.

In the model selection of AC servo motor, the motor power, revolving speed, voltage, driver with reducer or not, with brake or not, installed with encoder and so on must be taken into account. Many users are unfamiliar with these parameter requirements before model selection. As a AC motor supplier, ATO can help users to select the most appropriate motor model. And we will introduce a high quality and low cost AC servo motor. Powerful 400 watt servo motor at good price, features 1.27 Nm rated torque, 3000 rpm precise speed control. Continuous servo motor is available in a 60mm square flange size, widely used in industrial automation, embroidery machines, printing machinery, CNC machine, wood carving and other fields.

In the model selection of AC servo motor, the motor power, revolving speed, voltage, insulation class and so on must be taken into account. Many users are unfamiliar with these parameter requirements before model selection. As a industrial AC servo motor manufacturer, ATO can help users to select the most appropriate motor model. And we will introduce a high quality and high precision AC motor with 1 hp (750W) power rated, 3000 rpm speed.

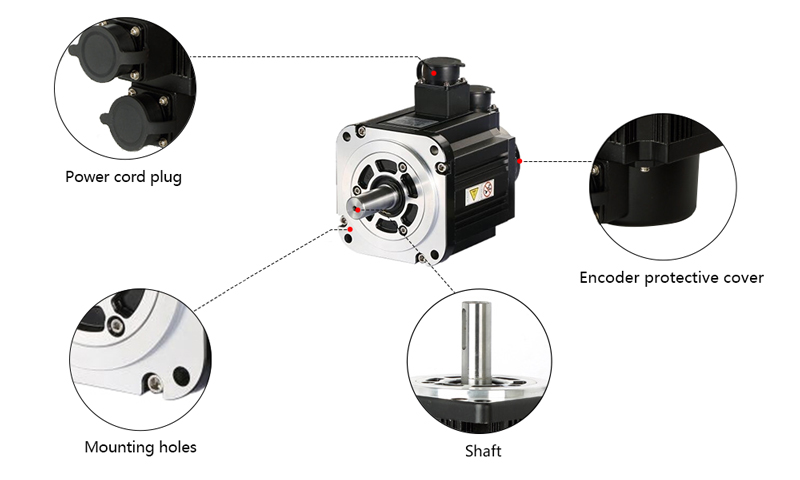

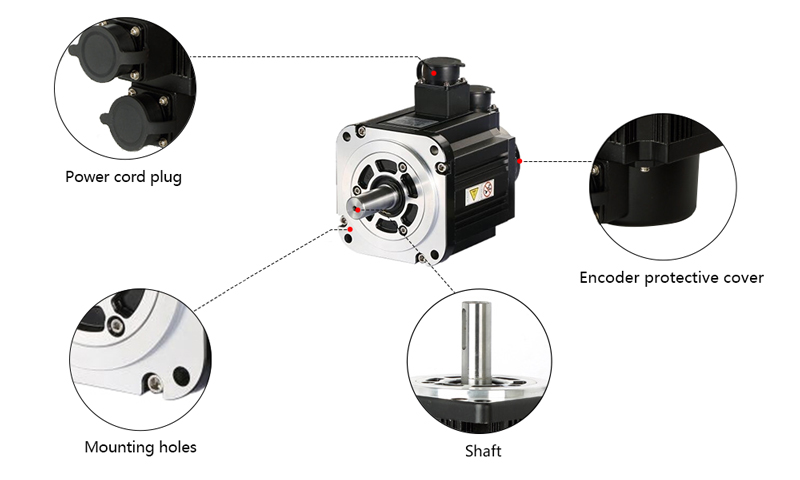

ATO heavy duty servo motors with strong anti-overload capability, able to withstand a load three times the rated torque, especially suitable for occasions with instant load fluctuations and requiring quick start. 1.5 kW (2 hp) AC servo motor produced in ATO is equipped with a feedback system. This feedback allows for real-time adjustments and precise control, making brushless AC servo motors ideal for applications demanding high-performance motion control.

2 kW high torque servo motor, brushless design, 3-phase 220V AC voltage, 2500 rpm, max speed up to 2800 rpm. Heavy duty electric servo motor is130mm square flange size, suitable for industrial automation, embroidery machines, printing machinery, CNC machine, wood carving and other fields.

Recently, ATO has released its latest electric AC servo motor with 5.5 kW. Whether small electrical apparatus or a large industrial equipment, this AC motor can be customized by the functional requirements of these appliances and direct sale by manufacturer. Compared with previous servo motors, this product has higher efficiency and service life.

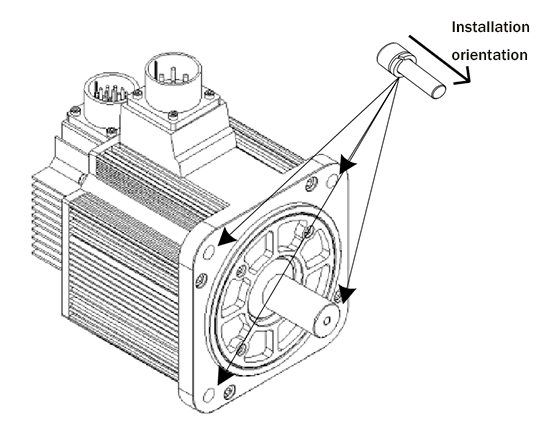

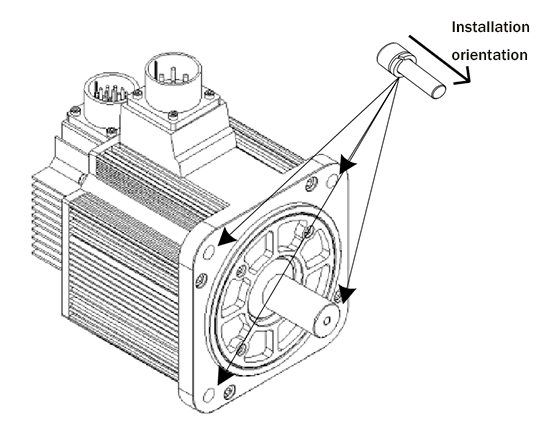

AC servo motor is a very important part of the AC servo system. AC servo motors play a key role in automation systems, so correct installation is critical to system performance and stability. Please observe the installation instructions described below to install the servo motor correctly. Servomotors can be mounted horizontally with the motor shaft oriented in the same direction as the machine shaft. When mounting an AC servo motor, the direction of the motor shaft should be the same as the direction of the mechanical shaft. This is to ensure that the motor operates properly and does not cause problems such as stalling or abnormal wear. If the direction of the motor shaft is not consistent with the direction of the mechanical shaft, it may lead to a mismatch between the motor and the mechanical load, affecting the performance and life of the motor.

Servomotors can be mounted horizontally with the motor shaft oriented in the same direction as the machine shaft. When mounting an AC servo motor, the direction of the motor shaft should be the same as the direction of the mechanical shaft. This is to ensure that the motor operates properly and does not cause problems such as stalling or abnormal wear. If the direction of the motor shaft is not consistent with the direction of the mechanical shaft, it may lead to a mismatch between the motor and the mechanical load, affecting the performance and life of the motor.

Servomotors can be mounted horizontally with the motor shaft oriented in the same direction as the machine shaft. When mounting an AC servo motor, the direction of the motor shaft should be the same as the direction of the mechanical shaft. This is to ensure that the motor operates properly and does not cause problems such as stalling or abnormal wear. If the direction of the motor shaft is not consistent with the direction of the mechanical shaft, it may lead to a mismatch between the motor and the mechanical load, affecting the performance and life of the motor.

Servomotors can be mounted horizontally with the motor shaft oriented in the same direction as the machine shaft. When mounting an AC servo motor, the direction of the motor shaft should be the same as the direction of the mechanical shaft. This is to ensure that the motor operates properly and does not cause problems such as stalling or abnormal wear. If the direction of the motor shaft is not consistent with the direction of the mechanical shaft, it may lead to a mismatch between the motor and the mechanical load, affecting the performance and life of the motor.

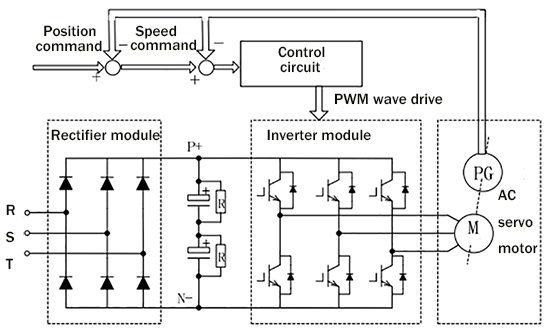

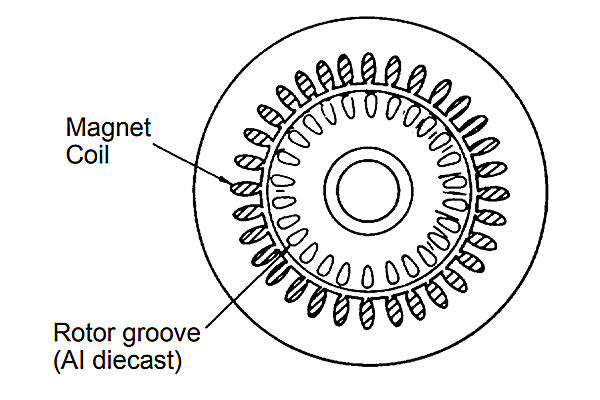

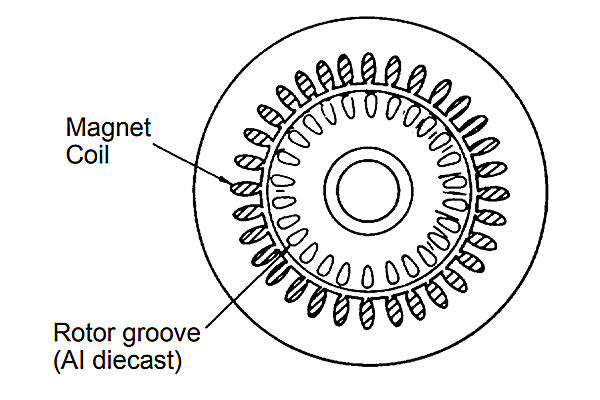

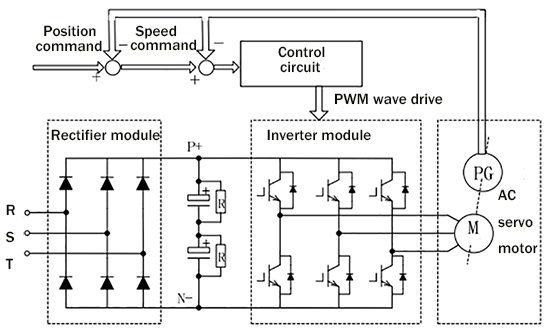

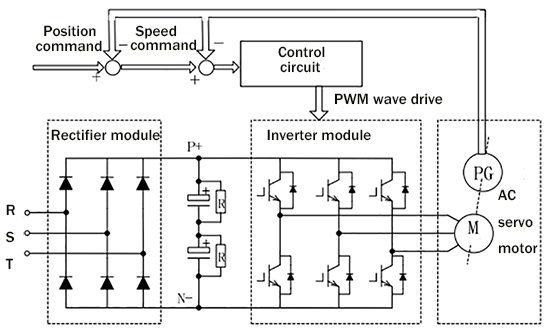

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally detects the motor speed and controls in such a way that the current flow in response to speed deviations, the servo motor can operate from a low speed to a high speed with a fixed torque. The operating principles of every small and large motor are the same with torque occurring according to Fleming's left-hand rule, which states that if a current flows through a conductor in a magnetic field, a force acts in the conductor. For SM-type (synchronous type) AC servo motors, a permanent magnet is provided in the rotor, a coil through which a current flows is provided in the magnet, and current that corresponds to the rotor operation (rotation speed/direction, output torque) flows through the magnet coil.

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The controller of the servo motor adjusts the drive current of the motor according to the position information fed back from the encoder, thus controlling the position and motion of the motor. In order for servo motors to operate better, it is necessary to understand the wiring method. Before wiring Do not bundle power and signal cables together or run them in the same pipe. Keep a distance of at least 300 mm between the power and signal cables. Signal lines and encoder feedback lines should be selected as twisted pair shielded lines or multi-core twisted pair shielded lines.

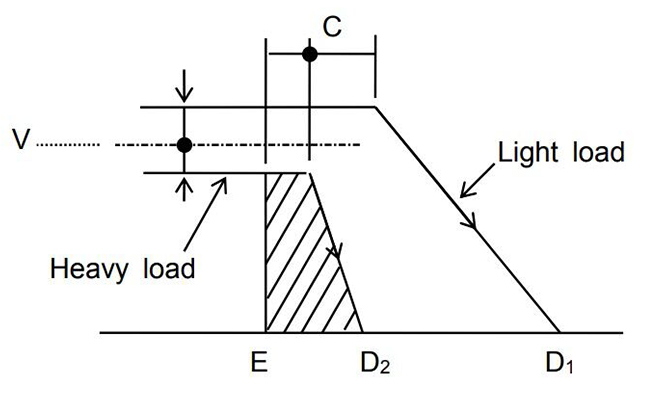

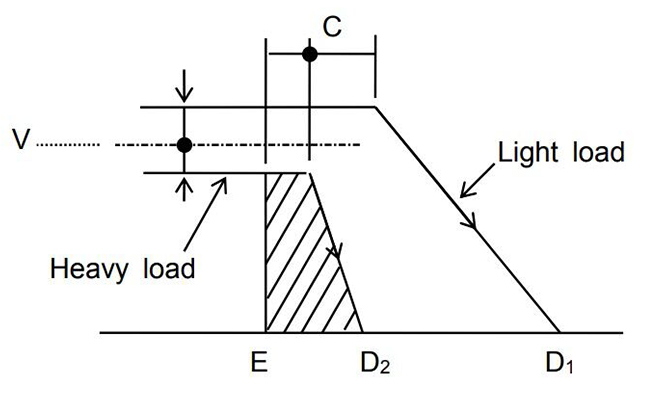

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an electrical method. Mechanical methods generally include putting a stopper (inverter stopping control and AC servo torque limiting are up to contact with the stopper) and forcible positioning methods of inserting an object into the cylinder, but there are restrictions on the stopping position. On the other hand, with an electrical method, positioning at many optional positions is easy by employing position sensors.

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast response and stability. Therefore, it is widely used in various applications that require precise control.

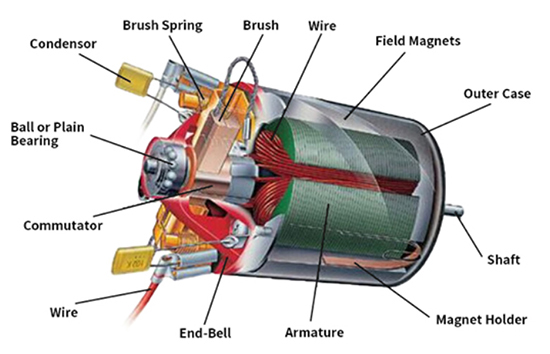

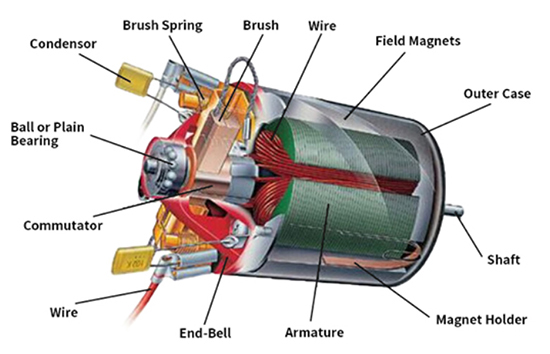

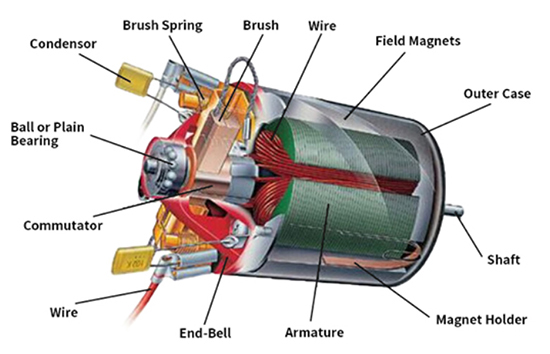

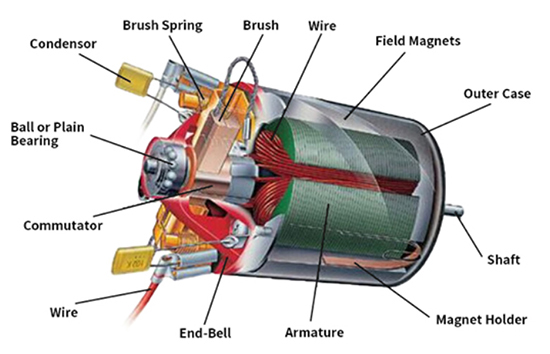

The stator consists of laminations and has salient poles. Usually, the stator poles are provided with two poles or four poles, and machine-wound excitation coils are used. The rotor is also laminated with slots to accommodate the armature windings. The rotor windings are connected to commutator segments mounted on the shaft. The stator and rotor windings are connected in series with the help of high-resistance brushes(placed on the commutator).

Armature reaction causes a reduction in air gap flux. To compensate for the same, compensating windings are connected in series with the stator winding.

Category

Featured Articles

What is Operation Principle of AC ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...How to Wire an AC Servo Motor?

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...What is Position Control by AC Servo?

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...AC Servo Motor: Structure, Working and ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...