Home » AC Servo Motor » 750W AC Servo Motor

750W AC Servo Motor

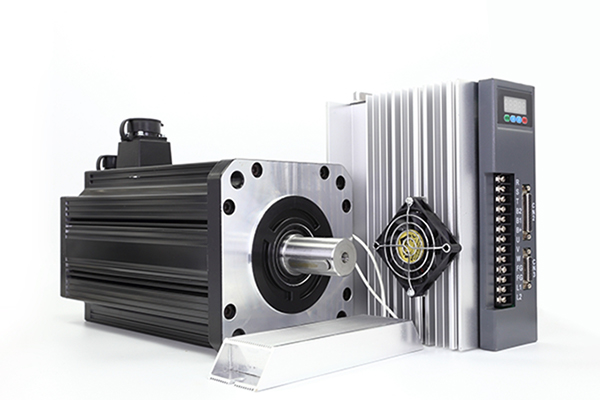

In the model selection of AC servo motor, the motor power, revolving speed, voltage, insulation class and so on must be taken into account. Many users are unfamiliar with these parameter requirements before model selection. As a industrial AC servo motor manufacturer, ATO can help users to select the most appropriate motor model. And we will introduce a high quality and high precision AC motor with 1 hp (750W) power rated, 3000 rpm speed.

Basic Specifications

Buy 750W AC Servo Motor Now!

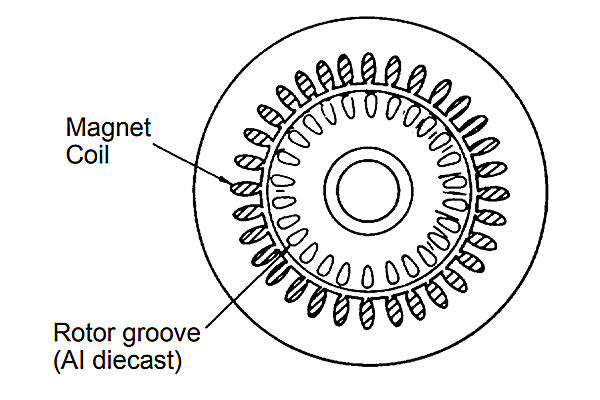

Many servomotors with high torque suffer from high braking torque (unenergized servomotors want to lock in certain positions more than others). They also often have significant distortions in their reaction potential characteristics, so even the best AC sine wave servo drives will inevitably produce torque ripple. These torque defects cause vibration and noise, affecting settling time performance and inducing servo seek. Smooth, quiet motion requires brushless servomotors with low torque moments and linear, low-pulsation torque output. Rotor balance and bearing quality are also important, especially at medium and high speeds.

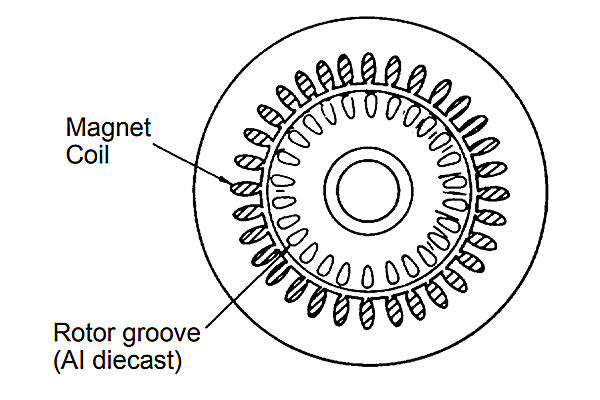

The magnetic design also has a significant impact on the noise and vibration of the motor. Over the past few years, it has become fashionable to use internal permanent magnet (IPM) rotor designs in servo motors in order to reduce costs.IPM designs concentrate the permanent magnetic flux by burying the permanent magnets in a laminated stack on the rotor shaft. Flux focusing allows the use of smaller and/or lower energy magnets, however, it can lead to large changes in inductance of the motor as it rotates, resulting in poor servo performance. It also induces pulsating, non-tangential forces within the motor, which can cause significant audible noise and vibration.

Basic Specifications

Model: ATO80SY-M02430

Rated Voltage:Single phase or three phase 220V AC

Matched Drive Model: ATO-SG-AS151000

Rated Current: 3.5A

Rated Speed: 3000 rpm

Max Speed: 3600 rpm

Square Flange Size: 80 mm

Rated Torque: 2.4 Nm

Peak Torque: 7.2 Nm

Insulation and Voltage Resistance: 1500V AC, 1 min

Insulation Class: Class B

Protection Class: IP54

Weight: 3 kg

Buy 750W AC Servo Motor Now!

Many servomotors with high torque suffer from high braking torque (unenergized servomotors want to lock in certain positions more than others). They also often have significant distortions in their reaction potential characteristics, so even the best AC sine wave servo drives will inevitably produce torque ripple. These torque defects cause vibration and noise, affecting settling time performance and inducing servo seek. Smooth, quiet motion requires brushless servomotors with low torque moments and linear, low-pulsation torque output. Rotor balance and bearing quality are also important, especially at medium and high speeds.

The magnetic design also has a significant impact on the noise and vibration of the motor. Over the past few years, it has become fashionable to use internal permanent magnet (IPM) rotor designs in servo motors in order to reduce costs.IPM designs concentrate the permanent magnetic flux by burying the permanent magnets in a laminated stack on the rotor shaft. Flux focusing allows the use of smaller and/or lower energy magnets, however, it can lead to large changes in inductance of the motor as it rotates, resulting in poor servo performance. It also induces pulsating, non-tangential forces within the motor, which can cause significant audible noise and vibration.

- Accuracy. ATO AC servo motors realize closed-loop control of position, speed and torque, overcome the problem of stepper motor out-of-step.

- Adaptability. ATO heavy duty servo motors with strong anti-overload capability, able to withstand a load three times the rated torque, especially suitable for occasions with instant load fluctuations and requiring quick start.

- Stable. Our AC brushless servo motors have smooth low-speed operation, no stepping phenomenon similar to stepper motor will occur when running at low speed, suitable for occasions occasions requiring fast response.

Post a Comment:

You may also like:

Category

Featured Articles

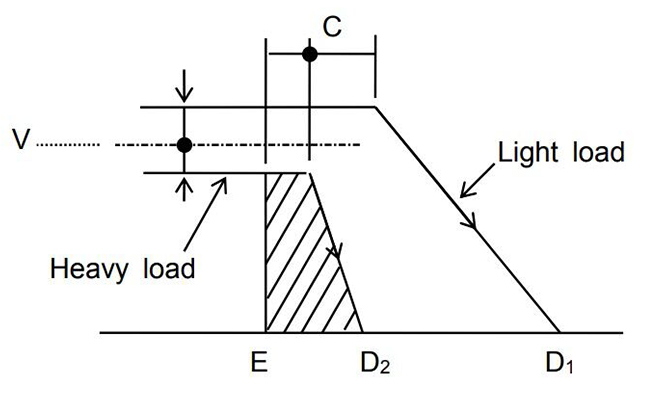

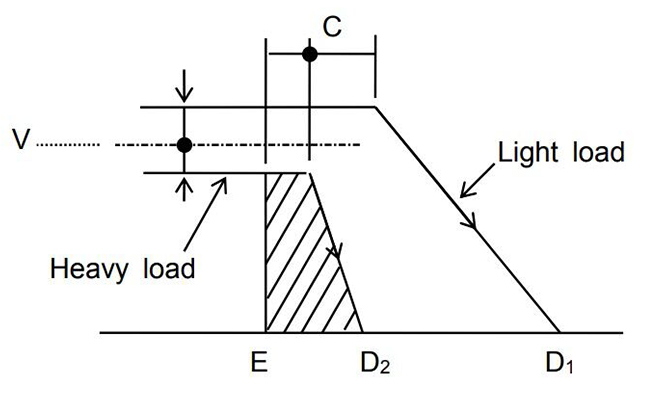

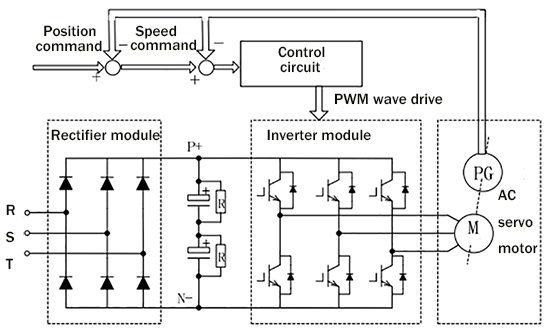

What is Position Control by AC Servo?

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...How to Wire an AC Servo Motor?

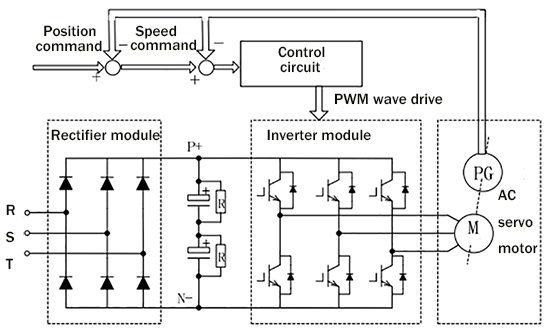

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

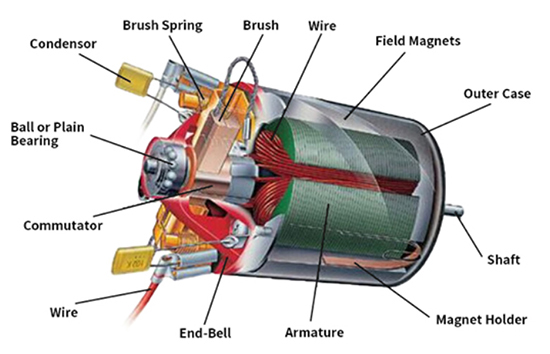

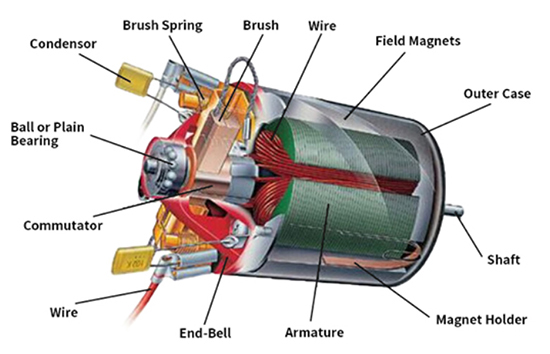

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...AC Servo Motor: Structure, Working and ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...What is Operation Principle of AC ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...