Home » DC Servo Motor » 400W 24V DC Servo Motor

400W 24V DC Servo Motor

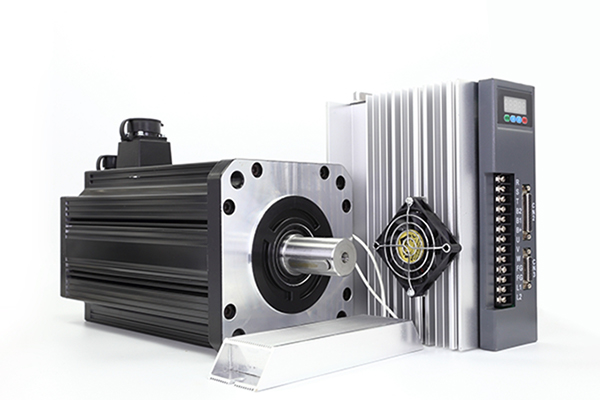

ATO provides 400W DC servo motors with IP55 protection and class F insulation in a ruggedized enclosure. DC servo motors are special motors made of NdFe35 permanent magnet material, which has strong demagnetization resistance and stable motor performance. 24V DC servo motors have the superior performance of low vibration, low noise and low inertia, so they are commonly used in numerical control machine tools, automated production lines, and medical equipment.

Specification

Model: ATO-80AS0204-15

Rated power: 400W

Rated voltage: 24V DC

Rated current: 21.3A

Rated torque: 2.55 Nm

Peak torque: 7.65 Nm

Rated speed: 1500 rpm

No-load speed: 1700 rpm

Working efficiency: 85%

Flange size: 80mm

Weight: 4 kg

For more information about the specifications of this motor or to purchase online, please feel free to contact us.

Next, we introduce the functional characteristics of this product. 400W DC servo motor has optimized and upgraded the winding end structure to achieve the purpose of minimizing copper loss and iron loss, and greatly improve the efficiency to 85%. And the DC servo motor has the advantages of high torque, fast dynamic response, wide speed range, and strong overload capacity (4 times). Low cost, easy to install and use, safety and quality are guaranteed by CE and ISO.

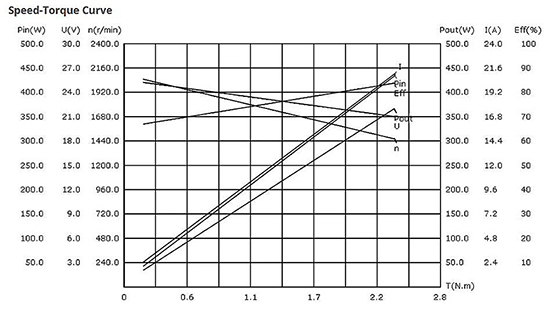

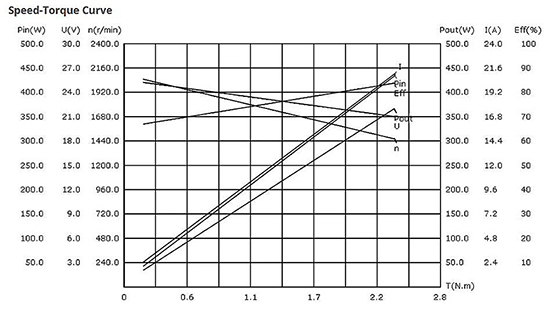

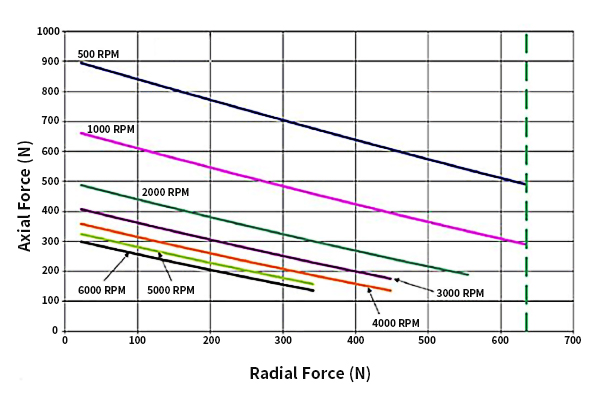

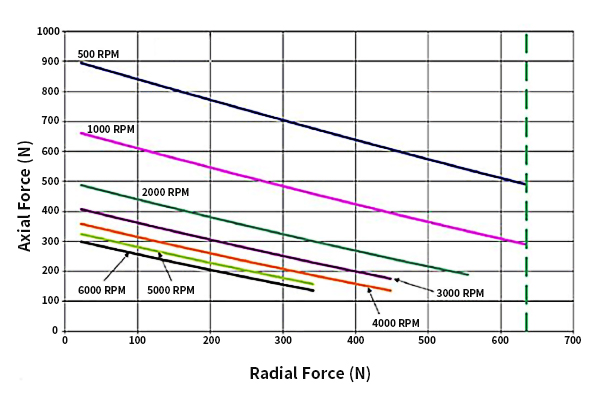

The speed torque curve of a servo motor is a curve that describes the relationship between the changes in output torque of the motor at different speeds. This curve usually shows the maximum torque, rated torque, and minimum torque of the motor at different speeds.

On the speed-torque curve of a servo motor, we can see that the output torque of the motor decreases as the speed increases. This is because as the speed increases, the output torque of the motor decreases. This is because as the speed increases, the physical characteristics of the current and magnetic field inside the motor will change, resulting in a decrease in the motor's This is because as the speed increases, the physical characteristics of the current and magnetic field inside the motor change, resulting in a decrease in the output torque.

In addition, the speed and torque curves of servo motors can be used to guide the selection and use of motors. For example, if a device needs to run at low speed under high torque, then a servo motor with large torque can be selected; if the device needs to run at high speed, then a servo motor with small torque can be selected.

It should be noted that the speed and torque curve of the servomotor is the characteristic of the motor itself, not the control mode of the motor. That is to say That is to say, no matter what kind of control method we use to control the servo motor, the speed and torque curve of the motor will not change.

Specification

Model: ATO-80AS0204-15

Rated power: 400W

Rated voltage: 24V DC

Rated current: 21.3A

Rated torque: 2.55 Nm

Peak torque: 7.65 Nm

Rated speed: 1500 rpm

No-load speed: 1700 rpm

Working efficiency: 85%

Flange size: 80mm

Weight: 4 kg

For more information about the specifications of this motor or to purchase online, please feel free to contact us.

Next, we introduce the functional characteristics of this product. 400W DC servo motor has optimized and upgraded the winding end structure to achieve the purpose of minimizing copper loss and iron loss, and greatly improve the efficiency to 85%. And the DC servo motor has the advantages of high torque, fast dynamic response, wide speed range, and strong overload capacity (4 times). Low cost, easy to install and use, safety and quality are guaranteed by CE and ISO.

The speed torque curve of a servo motor is a curve that describes the relationship between the changes in output torque of the motor at different speeds. This curve usually shows the maximum torque, rated torque, and minimum torque of the motor at different speeds.

In addition, the speed and torque curves of servo motors can be used to guide the selection and use of motors. For example, if a device needs to run at low speed under high torque, then a servo motor with large torque can be selected; if the device needs to run at high speed, then a servo motor with small torque can be selected.

It should be noted that the speed and torque curve of the servomotor is the characteristic of the motor itself, not the control mode of the motor. That is to say That is to say, no matter what kind of control method we use to control the servo motor, the speed and torque curve of the motor will not change.

Post a Comment:

You may also like:

Category

Featured Articles

What is a Servo Motor?

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

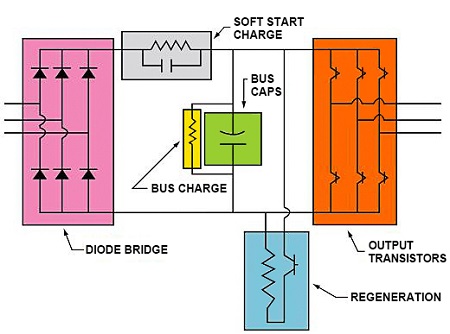

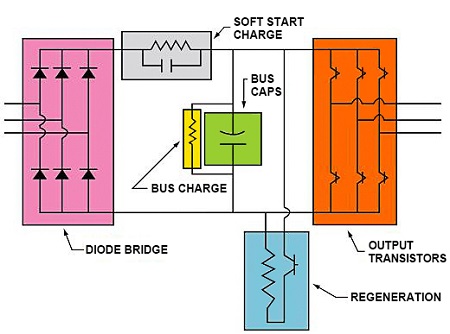

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...What are the Basics of Servo Drive?

Servo motors come in so many types and flavors that it is difficult to define them in a way that is accurate and universally ...

Servo motors come in so many types and flavors that it is difficult to define them in a way that is accurate and universally ...

Servo motors come in so many types and flavors that it is difficult to define them in a way that is accurate and universally ...

Servo motors come in so many types and flavors that it is difficult to define them in a way that is accurate and universally ...Why Use Servo Motor as Test Load?

Dynamometer is mainly divided into two parts: cabinet and frame, while the frame mainly has the motor under test, torque speed ...

Dynamometer is mainly divided into two parts: cabinet and frame, while the frame mainly has the motor under test, torque speed ...

Dynamometer is mainly divided into two parts: cabinet and frame, while the frame mainly has the motor under test, torque speed ...

Dynamometer is mainly divided into two parts: cabinet and frame, while the frame mainly has the motor under test, torque speed ...What Should Consider Before Using ...

Servo system is a commonly used control system, widely used in industrial automation. It compares the output signal with the ...

Servo system is a commonly used control system, widely used in industrial automation. It compares the output signal with the ...

Servo system is a commonly used control system, widely used in industrial automation. It compares the output signal with the ...

Servo system is a commonly used control system, widely used in industrial automation. It compares the output signal with the ...Servo Motor in Food Industry

In the ever-evolving landscape of the food industry, technological advancements play a pivotal role in enhancing efficiency, ...

In the ever-evolving landscape of the food industry, technological advancements play a pivotal role in enhancing efficiency, ...

In the ever-evolving landscape of the food industry, technological advancements play a pivotal role in enhancing efficiency, ...

In the ever-evolving landscape of the food industry, technological advancements play a pivotal role in enhancing efficiency, ...