Home » AC Servo Motor » 50W AC Servo Motor

50W AC Servo Motor

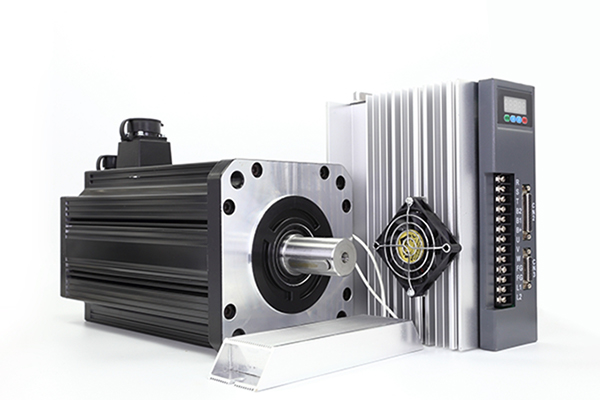

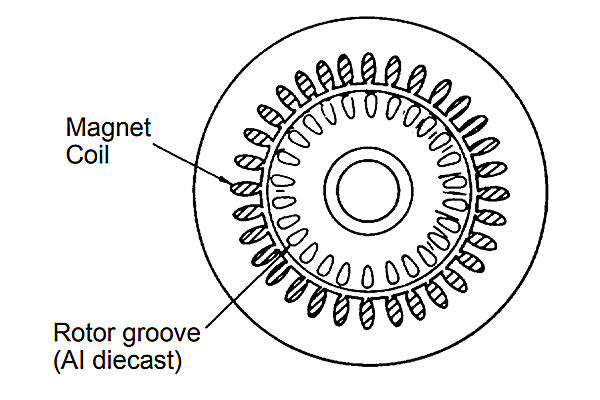

AC servo motor is a type of electric motor specifically designed for precise control of angular or linear position, velocity, and acceleration. ATO factory focuses on the production of high precision servo motors. 50W AC servo motor with brushless design, rated speed of 3000 rpm, maximum speed up to 3600 rpm. The detailed specification parameters of this electric servo motor are as follows.

Basic Specifications

Buy 50W AC Servo Motor Now!

The suitability of AC servo motors for harsh environmental conditions depends on the specific design and construction of the servo motor as well as the severity of the environmental conditions. In order to keep the 50W industrial servo motor running steadily in harsh environmental condition , the following points must be done:

Basic Specifications

Model: ATO40ST-M00130220

Rated Voltage: Single phase or three phase 220V AC

Matched Drive Model: ATOMG-1000

Rated Current: 0.4A

Rated Speed: 3000 rpm

Rated Torque: 0.16 N.m

Square Flange Size: 40 mm

Motor Length: 75 mm

Torque Coefficient: 0.4 N.m/A

Line-Line Resistance: 108 Ω

Electrical Time-Constant: 1.0 ms

Insulation Class: Class B

Protection Class: IP65

Weight: 0.47 kg

Buy 50W AC Servo Motor Now!

The suitability of AC servo motors for harsh environmental conditions depends on the specific design and construction of the servo motor as well as the severity of the environmental conditions. In order to keep the 50W industrial servo motor running steadily in harsh environmental condition , the following points must be done:

- AC servo motors often come with various levels of enclosure protection, specified by an IP (Ingress Protection) rating. The higher the IP rating, the more resistant the motor is to dust, water, and other environmental factors. For harsh conditions, choose a servo motor with a higher IP rating.

- In harsh environments where there may be exposure to corrosive substances, it's essential to choose a servo motor with appropriate materials and coatings to resist corrosion.

- If your application involves a dusty environment, motors with effective seals and filtering mechanisms can help prevent the ingress of dust and debris. Proper maintenance of the servo motor helps to extend the service time.

- High humidity levels can also impact motor performance and reliability. Servo motors designed for humid conditions should have appropriate seals and coatings to prevent moisture ingress.

-

Cooling and ventilation. Install a cooling system, such as a fan or heat sink, to maintain the optimal operating temperature of the servo motor. Consider the ambient temperature and humidity in the environment and design the cooling system accordingly.

-

Vibration and shock absorption. Implement vibration and shock absorption mechanisms to protect the servo motor from mechanical stress and vibrations that may occur in harsh conditions.

Post a Comment:

You may also like:

Category

Featured Articles

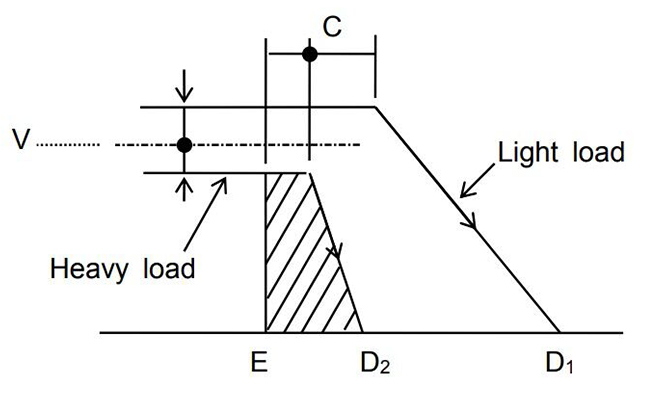

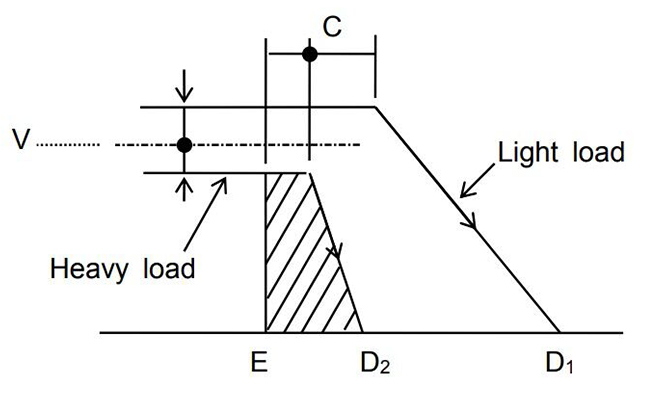

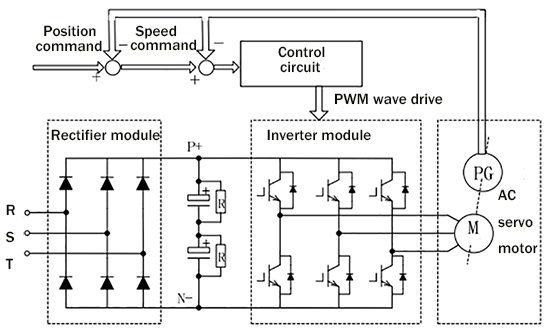

What is Position Control by AC Servo?

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...

The methods for stopping a moving object with prescribed accuracy at a fixed position consist of a mechanical method and an ...How to Wire an AC Servo Motor?

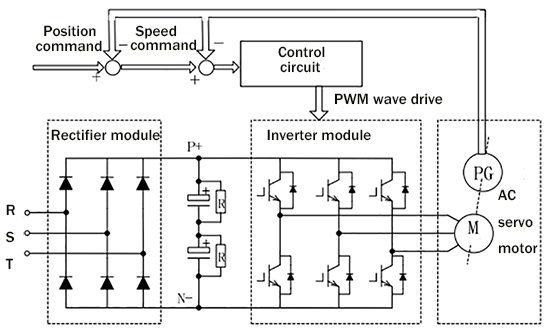

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...

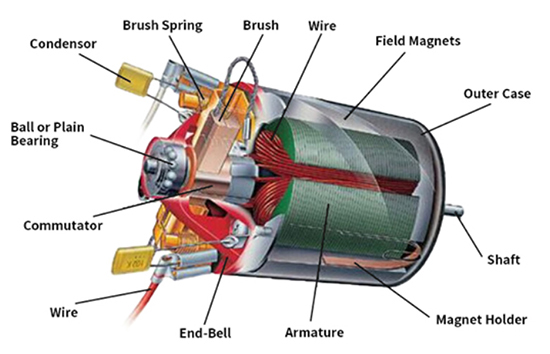

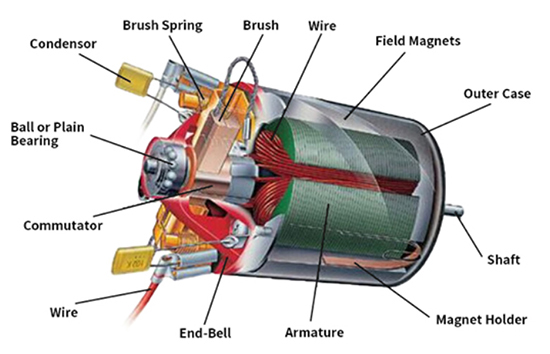

A servo motor is a type of motor that allows precise control of position, speed, and acceleration through a controller. The ...AC Servo Motor: Structure, Working and ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...

AC servo motor is a type of motor widely used in various industrial and commercial fields. It features high precision,fast ...What is Operation Principle of AC ...

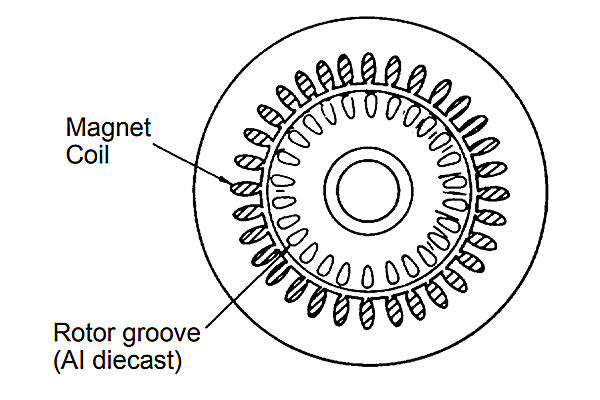

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...

The output torque of the servo motor is proportional to the current that flows in the motor. Because the servo amplifier normally ...