How to Maintain Servo Motor?

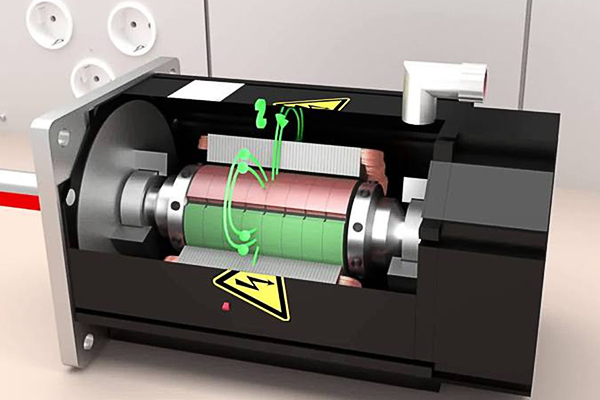

Serving as precision control devices in applications ranging from robotics to manufacturing processes, servo motors play a crucial role in various industries. To ensure optimal performance and longevity, it is essential to implement a systematic maintenance routine. In this article, we will explore the key steps and best practices for maintaining servo motors.

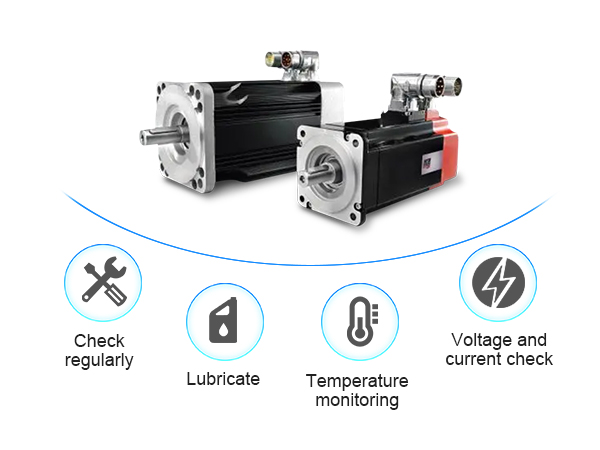

- Regular Inspection. Regular inspections are fundamental to identifying potential issues before they escalate. Conduct visual checks for loose connections, damaged cables, and any signs of wear and tear. Inspect the motor housing for debris or contaminants that could affect performance.

- Lubrication. Proper lubrication is critical for reducing friction and preventing premature wear of the motor components. Refer to the manufacturer's guidelines for the recommended lubrication schedule and use high-quality lubricants. Be cautious not to over-lubricate, as this can attract dust and dirt.

- Temperature Monitoring. Servo motors are sensitive to temperature fluctuations. Implement a temperature monitoring system to ensure that the motor operates within its specified temperature range. Overheating can lead to performance degradation and, in severe cases, permanent damage.

- Voltage and Current Checks. Regularly measure the voltage and current supplied to the servo motor. Deviations from the specified values could indicate electrical issues or impending motor failure. Voltage spikes or drops can be particularly damaging, so invest in surge protection devices if necessary.

- Feedback Device Calibration. Many servo motors rely on feedback devices such as encoders for precise control. Periodically calibrate these devices to ensure accurate position and speed feedback. Misalignment or malfunction of feedback devices can lead to inaccuracies in the motor's performance.

- Tightening Connections. Vibrations during operation can loosen electrical and mechanical connections. Regularly check and tighten bolts, screws, and other fasteners to prevent issues such as electrical arcing or mechanical failure. Use torque wrenches to ensure proper tightening without overloading components.

- Environmental Considerations. Evaluate the operating environment of the servo motor. Excessive humidity, dust, or corrosive substances can impact performance and lifespan. Implement measures such as protective enclosures or air filtration systems to mitigate environmental risks.

- Software Updates and Programming. Stay informed about software updates and programming changes provided by the servo motor manufacturer. Updating firmware and programming can enhance motor performance, add new features, and address any known issues.

- Emergency Stop System Testing. Test the emergency stop system regularly to ensure its effectiveness. This is crucial for preventing accidents and minimizing damage in the event of a malfunction or emergency.

- Documentation and Record-Keeping. Maintain comprehensive records of all maintenance activities, inspections, and repairs. This documentation can serve as a valuable reference for troubleshooting and planning future maintenance tasks.

Post a Comment:

You may also like:

Category

Featured Articles

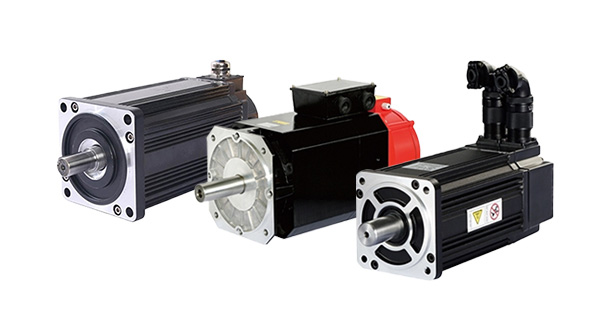

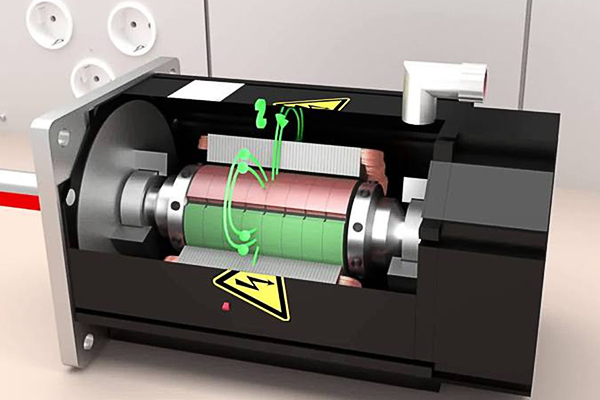

What is a Servo Motor?

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...How to Select the Suitable Power ...

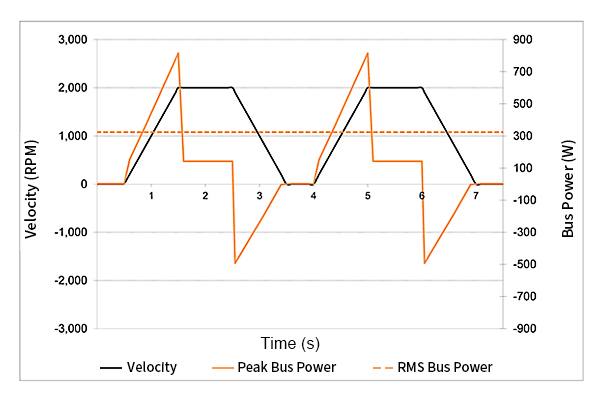

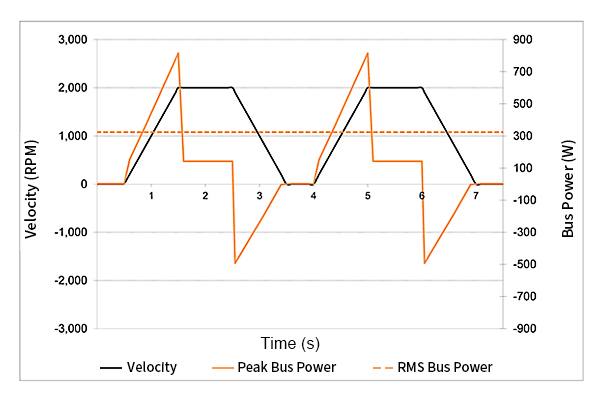

It's important to consider the unique demands of a motion control application when selecting a power supply. During ...

It's important to consider the unique demands of a motion control application when selecting a power supply. During ...

It's important to consider the unique demands of a motion control application when selecting a power supply. During ...

It's important to consider the unique demands of a motion control application when selecting a power supply. During ...What are the Types of Servo Motor?

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...How to Test Servo Motor?

Servo motors are devices that convert electrical signals into mechanical motion and are widely used in industrial automation, ...

Servo motors are devices that convert electrical signals into mechanical motion and are widely used in industrial automation, ...

Servo motors are devices that convert electrical signals into mechanical motion and are widely used in industrial automation, ...

Servo motors are devices that convert electrical signals into mechanical motion and are widely used in industrial automation, ...How to Maintain Servo Motor?

Servo motors play a crucial role in various industries, serving as precision control devices in applications ranging from ...

Servo motors play a crucial role in various industries, serving as precision control devices in applications ranging from ...

Servo motors play a crucial role in various industries, serving as precision control devices in applications ranging from ...

Servo motors play a crucial role in various industries, serving as precision control devices in applications ranging from ...