How to Measure Servo Motor Current?

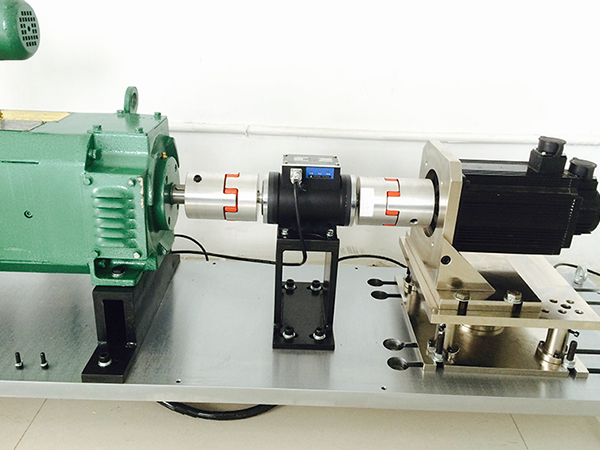

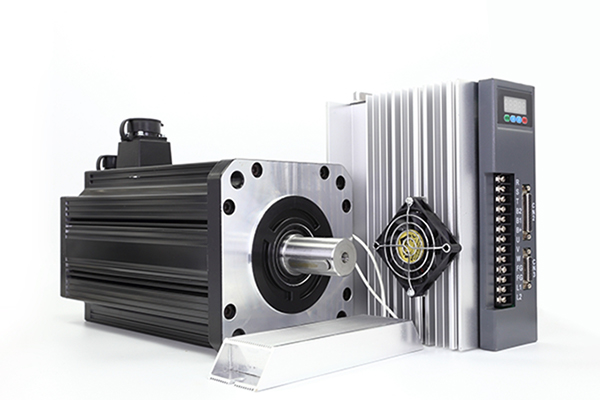

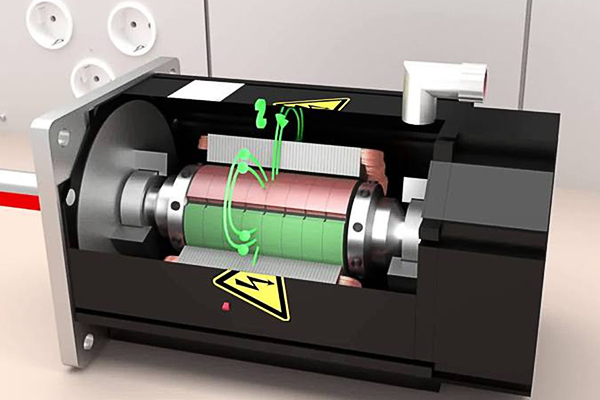

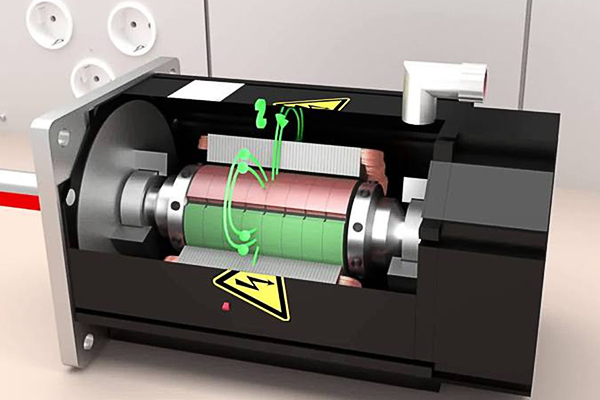

Servo motor is a kind of drive device widely used in various industrial automation and intelligent transportation fields. Its working principle is mainly based on the principle of electromagnetic induction, by controlling the speed and steering of the motor in order to achieve precise control. Servo motors have the advantages of high precision, fast response and stability, which make them play a key role in many demanding application scenarios. This article will focus on servo motor current measurement methods to help users better understand and utilize this device.

Importance of current measurement

Correctly measuring the current of servo motors is of great significance for monitoring the operating status of the equipment, early warning of faults and optimized control. Through the monitoring of the current, we can obtain the real-time load condition of the motor and determine whether its operating status is normal. At the same time, if the current exceeds the rated value, it may lead to overheating or even damage of the servo motor, so the accurate measurement of current is also a key link to prevent equipment failure.

Commonly used measurement methods

1. Direct method. The direct method is the simplest current measurement method, by installing a current sensor on the motor power line, the current value is obtained directly. The advantage of this method is simple and easy to implement, but may be affected by the power supply interference and the accuracy of the sensor.

2. Electric potential method. The electric potential method is used to deduce the current current value by measuring the motor's reverse electromotive force at a specific speed. This method does not require the installation of additional sensors on the power line, but it requires precise information about the rotational speed and has relatively low accuracy.

Experimental procedures and precautions

Take the direct method as an example, the experimental operation steps are as follows:

In fields such as industrial automation and intelligent transportation, the wide application of servo motors makes their current measurement results valuable. By monitoring and analyzing the current data, precise control and fault warning of the equipment can be realized, and production efficiency and quality can be improved. At the same time, ensuring the safe and stable operation of the equipment is of great significance in reducing maintenance costs and improving overall efficiency.

Through the discussion of servo motor current measurement methods, this article emphasizes the importance of correct current measurement for equipment operation status monitoring, fault early warning and optimal control. In practical applications, it is crucial to choose the appropriate measurement method according to different scenarios and needs. At the same time, the description of experimental operation steps and precautions makes this paper more practical and relevant. In conclusion, the correct measurement of servo motor current is of great significance to ensure the efficient and stable operation of the equipment as well as to ensure the safety of use.

Importance of current measurement

Correctly measuring the current of servo motors is of great significance for monitoring the operating status of the equipment, early warning of faults and optimized control. Through the monitoring of the current, we can obtain the real-time load condition of the motor and determine whether its operating status is normal. At the same time, if the current exceeds the rated value, it may lead to overheating or even damage of the servo motor, so the accurate measurement of current is also a key link to prevent equipment failure.

Commonly used measurement methods

1. Direct method. The direct method is the simplest current measurement method, by installing a current sensor on the motor power line, the current value is obtained directly. The advantage of this method is simple and easy to implement, but may be affected by the power supply interference and the accuracy of the sensor.

2. Electric potential method. The electric potential method is used to deduce the current current value by measuring the motor's reverse electromotive force at a specific speed. This method does not require the installation of additional sensors on the power line, but it requires precise information about the rotational speed and has relatively low accuracy.

Experimental procedures and precautions

Take the direct method as an example, the experimental operation steps are as follows:

- Prepare the required tools and materials, including current sensors, multimeters, screwdrivers and so on.

- Select a suitable current sensor and ensure that its range is greater than the maximum operating current of the motor.

- Connect the current sensor in series on the motor power line, note that the connection line should be as short as possible to minimize interference.

- Turn on the power, observe and record the current reading of the motor.

- At the end of the experiment, turn off the power supply and then remove the current sensor.

- Make sure the power supply voltage is stable before conducting the experiment to avoid influencing the measurement results.

- When connecting the current sensor, pay attention to the polarity of the connecting wires to avoid inaccurate measurement results caused by reversing the connection.

- In the course of the experiment, if there is any abnormal situation, stop the experiment immediately and remove the problem before measurement.

In fields such as industrial automation and intelligent transportation, the wide application of servo motors makes their current measurement results valuable. By monitoring and analyzing the current data, precise control and fault warning of the equipment can be realized, and production efficiency and quality can be improved. At the same time, ensuring the safe and stable operation of the equipment is of great significance in reducing maintenance costs and improving overall efficiency.

Through the discussion of servo motor current measurement methods, this article emphasizes the importance of correct current measurement for equipment operation status monitoring, fault early warning and optimal control. In practical applications, it is crucial to choose the appropriate measurement method according to different scenarios and needs. At the same time, the description of experimental operation steps and precautions makes this paper more practical and relevant. In conclusion, the correct measurement of servo motor current is of great significance to ensure the efficient and stable operation of the equipment as well as to ensure the safety of use.

Post a Comment:

You may also like:

Category

Featured Articles

How to Test Servo Motor?

Servo motors are devices that convert electrical signals into mechanical motion and are widely used in industrial automation, ...

Servo motors are devices that convert electrical signals into mechanical motion and are widely used in industrial automation, ...

Servo motors are devices that convert electrical signals into mechanical motion and are widely used in industrial automation, ...

Servo motors are devices that convert electrical signals into mechanical motion and are widely used in industrial automation, ...What is a Servo Motor?

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...How to Maintain Servo Motor?

Servo motors play a crucial role in various industries, serving as precision control devices in applications ranging from ...

Servo motors play a crucial role in various industries, serving as precision control devices in applications ranging from ...

Servo motors play a crucial role in various industries, serving as precision control devices in applications ranging from ...

Servo motors play a crucial role in various industries, serving as precision control devices in applications ranging from ...What are the Types of Servo Motor?

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...

There are some special types of application of electrical motor where rotation of the motor is required for just a certain angle ...How to Select the Suitable Power ...

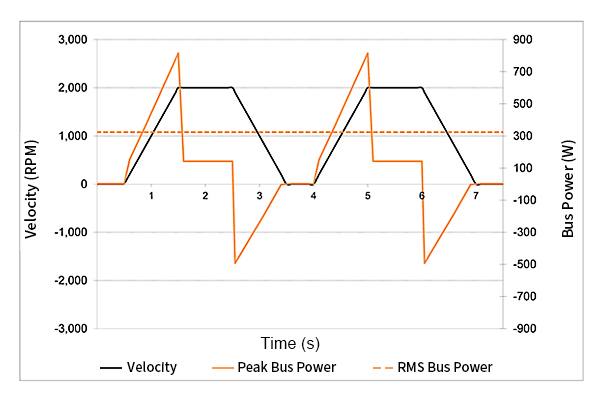

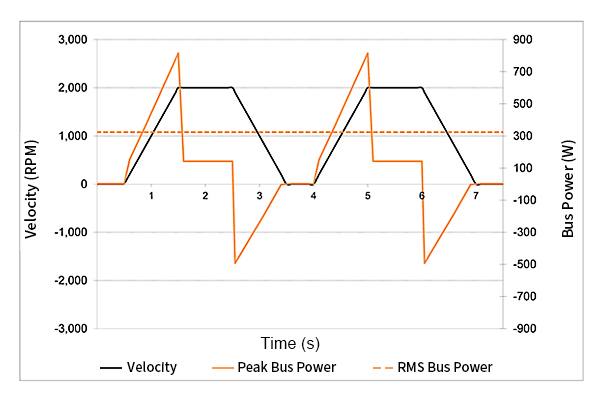

It's important to consider the unique demands of a motion control application when selecting a power supply. During ...

It's important to consider the unique demands of a motion control application when selecting a power supply. During ...

It's important to consider the unique demands of a motion control application when selecting a power supply. During ...

It's important to consider the unique demands of a motion control application when selecting a power supply. During ...