Home » Application » Servo Drives for Electric Mobility

Servo Drives for Electric Mobility

Servo drives play a crucial role in electric mobility applications, providing precise control of electric motors for various purposes, such as propulsion, steering, and braking in electric vehicles (EVs) and other electric mobility devices.

Consideration Factor

Reliable Performance

Reliable Performance

Consideration Factor

-

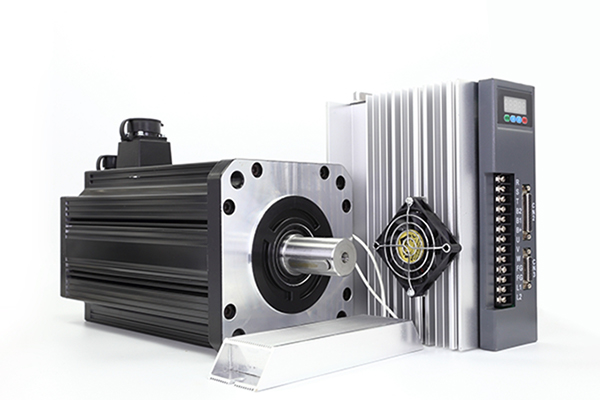

Brushless DC (BLDC) Motors: electric mobility systems often use brushless DC motors due to their efficiency, reliability, and compact size. Servo drives are designed to control these motors effectively. High t

orque and power density: servo drives in electric mobility applications need to provide high torque and power density to ensure efficient and responsive performance.Regenerative braking: many electric mobility systems utilize regenerative braking to recover energy during deceleration. Servo drives should support regenerative braking to improve overall energy efficiency.Integration with inverters: servo drives are often integrated with inverters to form a compact and lightweight unit. This integration is crucial for electric mobility applications where space and weight considerations are significant.

orque and power density: servo drives in electric mobility applications need to provide high torque and power density to ensure efficient and responsive performance.Regenerative braking: many electric mobility systems utilize regenerative braking to recover energy during deceleration. Servo drives should support regenerative braking to improve overall energy efficiency.Integration with inverters: servo drives are often integrated with inverters to form a compact and lightweight unit. This integration is crucial for electric mobility applications where space and weight considerations are significant.

- CAN (Controller Area Network): servo drives in electric mobility often communicate using the CAN protocol, which is widely used in automotive applications for real-time data exchange between components.

- Fault Detection and Protection: servo drives should incorporate safety features such as fault detection and protection mechanisms to ensure the reliable operation of electric mobility systems.

- Heat Dissipation: electric mobility applications, especially EVs, generate heat during operation. Servo drives need effective heat dissipation mechanisms to maintain optimal operating temperatures and ensure long-term reliability.

- Configurability: the ability to customize and configure servo drives for specific electric mobility applications is essential. This adaptability allows manufacturers to optimize performance based on the requirements of different vehicles.

- Automotive Standards: servo drives used in electric mobility should comply with relevant automotive industry standards to ensure safety, interoperability, and regulatory compliance.

- Efficient Operation: servo drives should be designed for energy efficiency to maximize the driving range of electric vehicles and reduce overall energy consumption.

- Robust Design: the harsh operating conditions of electric mobility applications require servo drives to have a robust design to withstand vibrations, temperature variations, and other environmental factors.

- Motor Type: servo drives are compatible with various types of electric motors, such as brushless DC (BLDC) motors, permanent magnet synchronous motors (PMSM), and induction motors. The choice depends on the specific application requirements.

- Power and Torque Ratings: the servo drive must be matched with the power and torque requirements of the electric motor to ensure optimal performance in electric mobility applications. The drive should provide sufficient power for acceleration, cruising, and other operating conditions.

- Regenerative Braking: many electric mobility systems utilize regenerative braking to recover energy during deceleration. Servo drives should support regenerative braking functionality to improve overall energy efficiency and extend the vehicle's range.

- Compact Design: space is often limited in electric vehicles, so servo drives should be designed to be compact and lightweight. Integration with other power electronics components, such as inverters, can help reduce the overall size of the electric propulsion system.

- High Efficiency: efficiency is crucial for electric mobility to maximize the driving range and overall energy efficiency of the vehicle. Servo drives should be designed to minimize energy losses during motor control operations.

- Communication Protocols: electric mobility systems often rely on communication between various components. Servo drives should support communication protocols commonly used in automotive applications, such as Controller Area Network (CAN) and others.

- Safety Features: Servo drives should incorporate safety features, including fault detection and protection mechanisms, to ensure the safety of the vehicle and its occupants. This is especially important in dynamic and safety-critical electric mobility applications.

- Temperature Management: Efficient heat dissipation is crucial for the reliable operation of servo drives in electric mobility. They should be equipped with effective thermal management systems to handle the heat generated during operation.

- Customization and Flexibility: Electric mobility applications vary widely, and servo drives should offer customization options to meet the specific requirements of different vehicle types and usage scenarios.

- Compliance with Automotive Standards: Servo drives should adhere to relevant automotive industry standards and regulations to ensure safety, reliability, and compliance with industry norms.

- Robustness and Durability: Electric mobility applications expose components to various environmental conditions and stresses. Servo drives should be designed to be robust and durable, capable of withstanding vibrations, temperature fluctuations, and other challenging conditions.

- Integration with Vehicle Control Systems: Servo drives need to seamlessly integrate with the overall vehicle control system, collaborating with other components such as sensors, controllers, and battery management systems to ensure coordinated and efficient operation.

Post a Comment:

You may also like:

Category

Featured Articles

Servo Motor in Medical Industry

With the continuous development of technology, servo motors are being used more and more widely in medical equipment. Servo ...

With the continuous development of technology, servo motors are being used more and more widely in medical equipment. Servo ...

With the continuous development of technology, servo motors are being used more and more widely in medical equipment. Servo ...

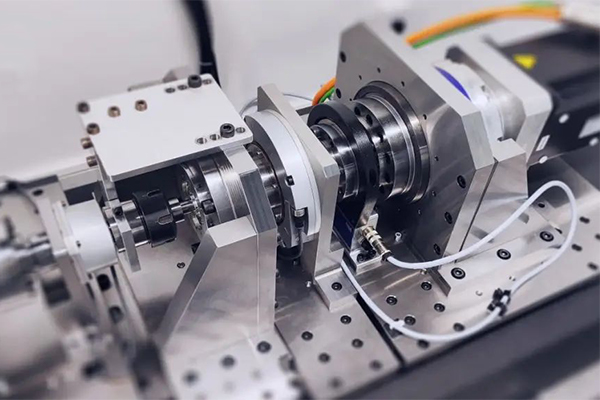

With the continuous development of technology, servo motors are being used more and more widely in medical equipment. Servo ...Servo System in CNC Machine Tools

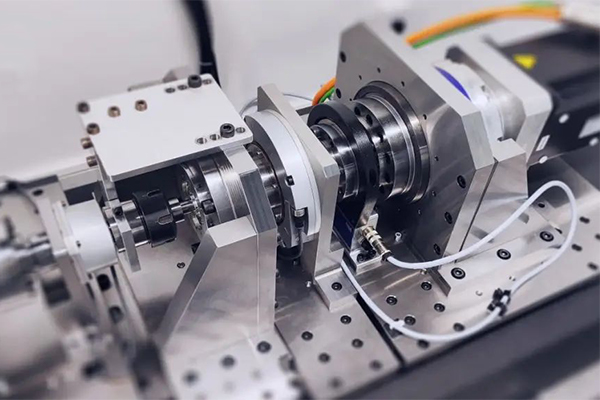

As the actuator of CNC machine tools, servo system integrates power electronics, control, drive and protection, and with the ...

As the actuator of CNC machine tools, servo system integrates power electronics, control, drive and protection, and with the ...

As the actuator of CNC machine tools, servo system integrates power electronics, control, drive and protection, and with the ...

As the actuator of CNC machine tools, servo system integrates power electronics, control, drive and protection, and with the ...Equation Derivation for Servo Motor

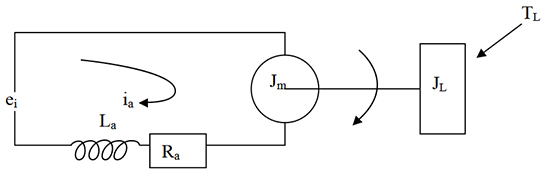

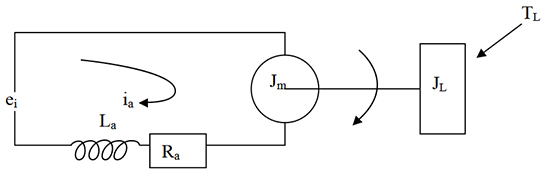

In the analysis of electric servo drive motors , the equations for the motor indicates the presence of two time constants. One is ...

In the analysis of electric servo drive motors , the equations for the motor indicates the presence of two time constants. One is ...

In the analysis of electric servo drive motors , the equations for the motor indicates the presence of two time constants. One is ...

In the analysis of electric servo drive motors , the equations for the motor indicates the presence of two time constants. One is ...Servo Motor in Food Industry

In the ever-evolving landscape of the food industry, technological advancements play a pivotal role in enhancing efficiency, ...

In the ever-evolving landscape of the food industry, technological advancements play a pivotal role in enhancing efficiency, ...

In the ever-evolving landscape of the food industry, technological advancements play a pivotal role in enhancing efficiency, ...

In the ever-evolving landscape of the food industry, technological advancements play a pivotal role in enhancing efficiency, ...Servo Drives for Electric Mobility

Servo drives play a crucial role in electric mobility applications, providing precise control of electric motors for various ...

Servo drives play a crucial role in electric mobility applications, providing precise control of electric motors for various ...

Servo drives play a crucial role in electric mobility applications, providing precise control of electric motors for various ...

Servo drives play a crucial role in electric mobility applications, providing precise control of electric motors for various ...